What are the differences between glass mat and glass cloth?

Glass cloth and glass mat are often mentioned interchangeably. Despite their similar use, the two materials differ from a structural standpoint.

Glass cloth and glass mat are constituents of composites with different structures. In fact, these composites are remarkably different.

Composition, use and benefits of glass mat

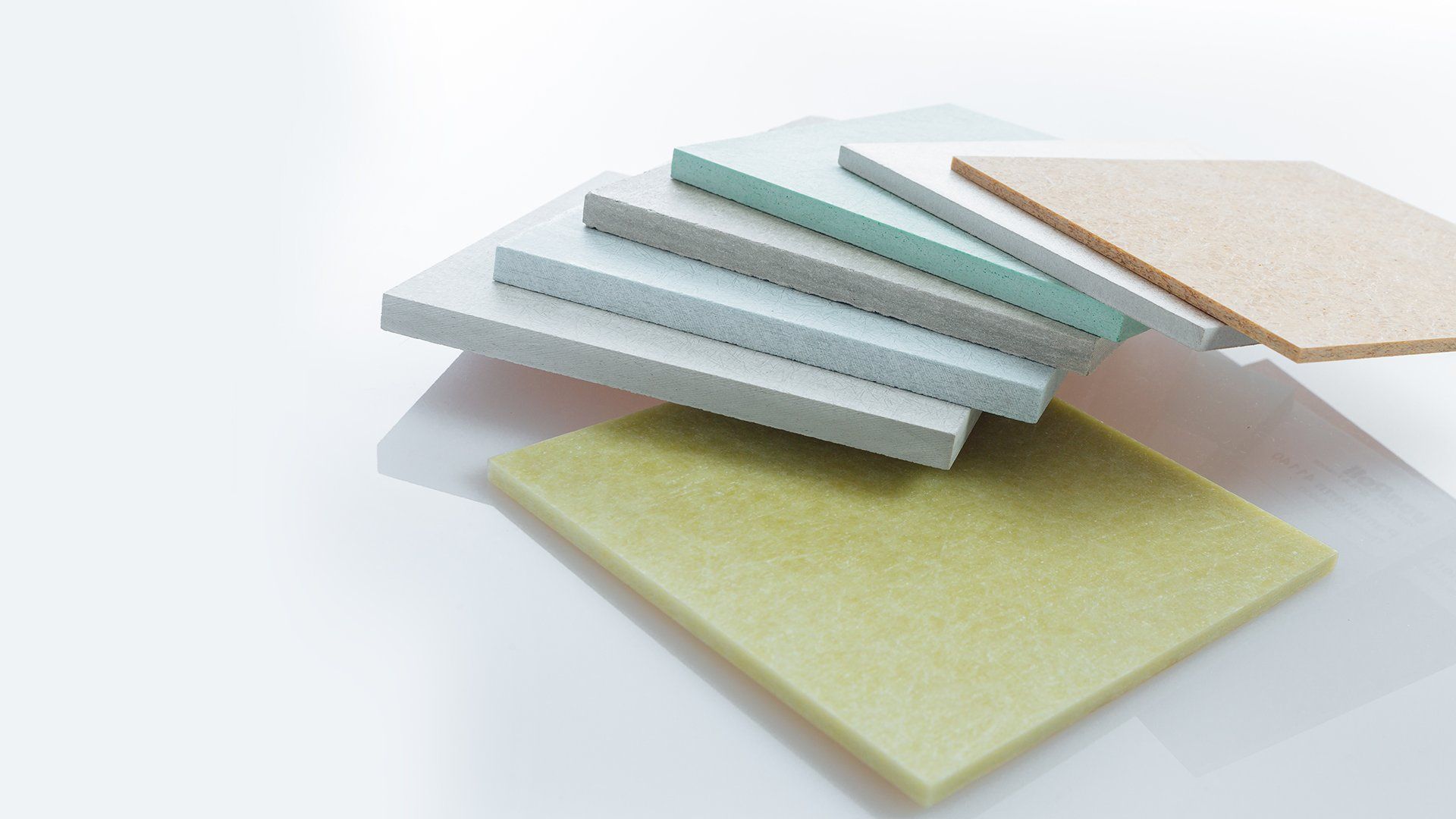

Glass mat is a widely used composite material in many fields: shipbuilding, swimming pools and roofs in the construction industry, wind turbines and car body parts. With respect to Isola, glass mat is actively used for our manufacturing composites.

Glass mat is a specific cloth type made from long or short glass fibers assembled with a binding agent. Because of this technical breakthrough, it is now possible to produce new composites more adapted to electrical insulation applications and the necessary technical and economic specifications. Thanks to this non-woven structure, the percentage of glass in laminates can be adjusted to the right mechanical characteristics.

Benefits of glass mat composites

Unlike glass cloth, glass mat is not woven, making it a more cost-effective component since it guarantees a more streamlined glass fiber assembly process.

The fibers are randomly arranged, but much more standardized in terms of length and verticality. Composite materials made from glass mat are mechanically standardized, regardless of a plate’s machining direction.

This standardized form also increases the stability of the machined parts, whether they are produced in the length or width direction of the plate. This stability is critical in multiple fields.

Another notable benefit is the improvement in shear tests for glass mat laminates. The 3D pressing of glass mat reduces the layering effect of glass cloths, producing more cohesive laminate layering.

This structure also helps to facilitate the machinability of glass mat materials. For instance, when we compare two materials of the same epoxy resin—one with glass mat and the other with glass cloth—the key point is the potential for machining laminates faster (20%) using glass mat, thereby extending the life cycle (25%) of diamond and carbide tools.

For many years, Isola Composite has worked with this technical development to produce composite materials that are (i) more cost-effective as regards structure and machinability, and (ii) more adapted to the technical requirements of electrical and mechanical insulation, not to mention density as well as fire and UV resistance.

That said, at present, not all materials can be developed from glass mat.

Composition and use of glass cloth

As with glass mat, glass cloth - or fiberglass cloth – is a constituent of the composite material structures. Essentially, unlike mat, glass cloth requires weaving and an additional prepreg step before it is pressed into a composite.

On the one hand, glass cloth is more mechanically resistant than mat. On the other, it’s less malleable. Like glass mat, multiple glass cloth types exist such as twill and weave. Which type of glass cloth you use will depend on your exact project specifications.

Isola Composite supplies the best prepreg assemblies, adapting composite laminates to meet your project needs.

Glass cloth is not used in the same way as glass mat. It must be prepregnated before pressing. Remember: prepreg maturing is a gradual process, and its storage must be controlled.

Glass cloth offers natural strength due to its weave, but it also tends to deteriorate more quickly than glass mat, before it “delaminates” or “peels.” One potential solution to this is to develop alternating layers of glass cloth and glass mat.

In summary, these two materials have different properties, but their use can actually be combined.